As your business scales, so do your logistics needs. Your warehouse, once perfectly sized, may now be holding you back. From operational slowdowns to storage overflows, there are clear indicators that it’s time to reevaluate your facility.

Let’s explore the top 5 signs your business has outgrown its warehouse space—and what you can do about it.

1. Inventory Is Overflowing Into Aisles or Common Areas

If pallets are stacked in walkways, packing zones, or even office corners, your space is no longer functional—or safe.

Inventory should be stored in a way that is organized, accessible, and compliant with safety regulations. When stock starts taking over shared spaces, it disrupts productivity, slows down picking efficiency, and increases the risk of accidents and workplace injuries.

Additionally, crowded storage areas make inventory management systems less reliable, leading to miscounts and stock discrepancies.

2. Order Fulfillment Is Slowing Down

Efficient picking, packing, and shipping are vital to meeting customer expectations. If your team struggles to keep up with order volume, your warehouse layout—or lack of space—could be the problem.

Signs include:

– Frequent picking errors

– Longer lead times

– Missed shipping deadlines

– Rising return or complaint rates

This slowdown not only impacts customer satisfaction but also burdens your staff and drives up fulfillment costs.

3. You’ve Started Using Offsite Storage (Again)

Temporary storage facilities might seem like a quick fix—but they’re often a costly patch. Moving inventory back and forth adds transportation costs, delays, and communication gaps between systems.

If offsite storage has become part of your regular workflow, it’s time to consider a permanent, scalable solution—whether that’s a larger facility or a reliable third-party logistics (3PL) partner.

4. Seasonal Peaks Are Becoming Unmanageable

Does your warehouse feel like a war zone during Black Friday, the holidays, or seasonal product launches?

If peak periods overwhelm your staff, overflow your space, and disrupt daily operations, your infrastructure may not be built to scale. Seasonal volume spikes are normal—but they shouldn’t throw your entire supply chain into chaos.

Working with a 3PL that offers on-demand warehousing and flexible space during busy seasons can help you manage volume without overcommitting long-term.

5. You’re Holding Back Growth to Avoid Space Issues

This is the clearest red flag of all: when your team avoids launching new SKUs, entering new markets, or onboarding new clients because you “don’t have the space.”

Your warehouse shouldn’t be a barrier to innovation. If logistics limitations are stifling your ability to scale, then the cost of inaction is far greater than the cost of upgrading.

Is It Time to Expand or Outsource?

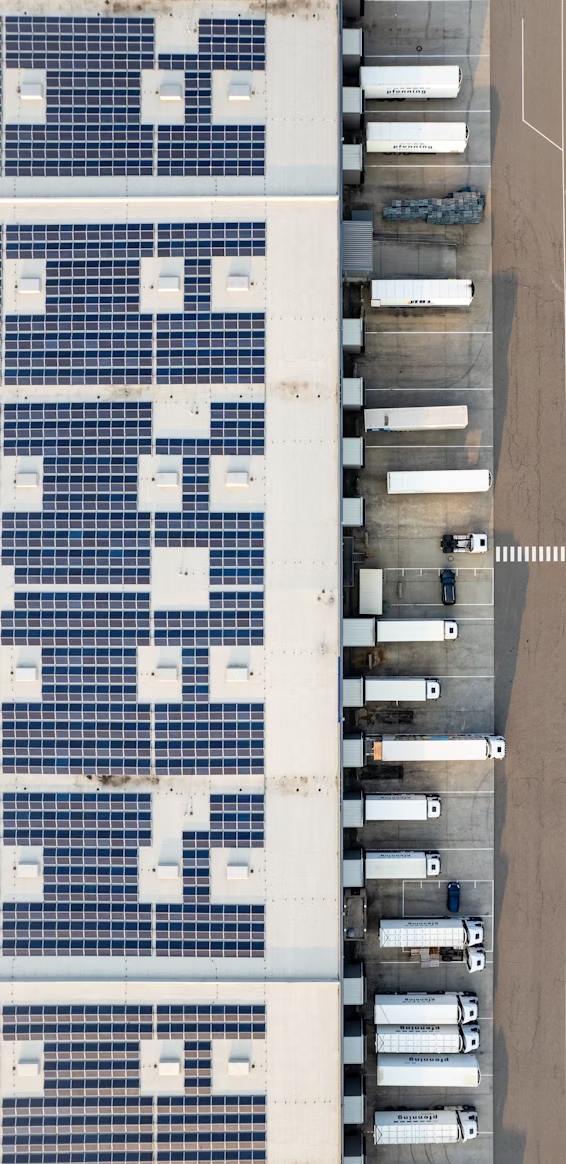

If any of these signs sound familiar, it’s time to take a serious look at your warehousing strategy. Whether you expand into a larger facility or partner with a 3PL, the right move will unlock efficiency, reduce costs, and support long-term growth.

At Rolls Right Distribution Centre, we offer:

Over 200,000 sq ft of modern, secure warehouse space

Temperature-controlled zones for sensitive goods

Flexible storage and fulfillment solutions that grow with you

Expertise in B2B and D2C logistics

We help businesses work smarter—without growing pains.